24/7 Emergency Service, Repair & Maintenance

Wolverine provides emergency service and repair 24 hours a day 365 days a year.

- Abnormal, erratic or unpredictable behavior of a crane should be inspected and evaluated to prevent personal injury and further damage to equipment

Crane Service

Regularly servicing a crane can eliminate costly periods of extensive downtime while serious yet preventable breakdowns are corrected.

- Preventative maintenance programs

- Certified crane inspections

- Troubleshooting

- Recommendations

- Certified complete repair

- Modernizations

Crane Logic Service Program

Wolverine Crane provides an industry leading service program focused on reducing overall downtime and expenses while increasing crane longevity.

Wolverine Crane provides an industry leading service program focused on reducing overall downtime and expenses while increasing crane longevity.

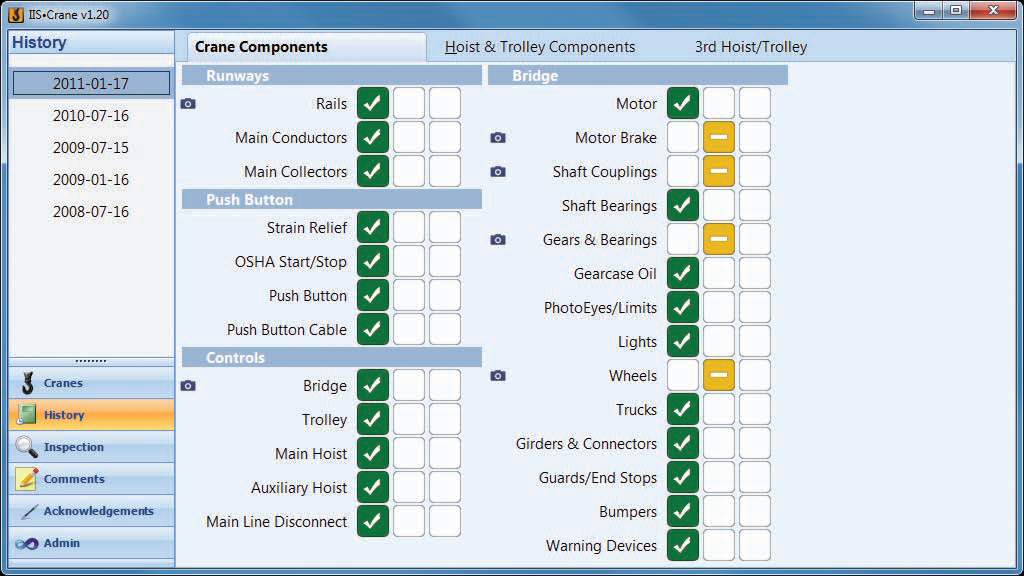

- Industry leading inspection software improves efficiency and quality of service processes

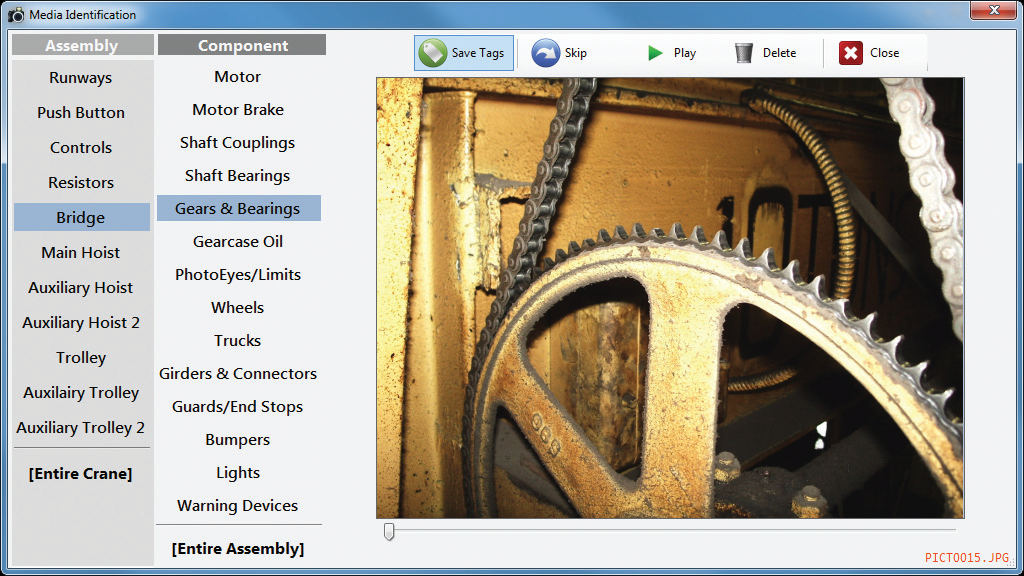

- Our industry leading inspection software provides a detailed but concise electronic report covering all crane & hoist components.

- Any deficiencies found will be listed with detailed written description and attached photo or video clip for further clarification and review.

- Our inspections are in accordance with OSHA 1910.179 “periodic” or “frequent” requirements.

- Preventative maintenance can eliminate costly periods of extensive downtime while serious yet preventable breakdowns are corrected.

- Be proactive in your maintenance program rather than reactive. Direct the appropriate attention to those component items which require monitoring.

- Maintaining your investment over the long term.

- Predictive planning for future repairs.

- Regular service and inspections are the first step in preventative maintenance.

- Repair plan development

- Develop a plan to maintain the reliable operation of your equipment within your maintenance budget.

- Addressing the components causing repetitive repair issues saves you money over time and increases your equipment’s reliability.

- Our goal is to positively enhance your plant productivity and maximize your return on investment

Crane Inspections

Crane inspections are a form of preventative maintenance and an important component of our service program. They are a simple means of maintaining company productivity by reducing overall downtime while also preventing crane related injury.

Crane inspections are a form of preventative maintenance and an important component of our service program. They are a simple means of maintaining company productivity by reducing overall downtime while also preventing crane related injury.

- Well maintained cranes are safer, last longer, and cost less to operate

- Help avoid costly repairs & downtime

- MIOSHA requires inspections of cranes, hoists and lifting equipment

- What is included in an inspection?

- Components requiring lubricant are oiled/greased

- Brakes, emergency systems and safety equipment are inspected and/or tested

- General operation is evaluated for irregularity and abnormal behavior

- Final report is printed immediately at the conclusion of the inspection

- Copies of reports should be stored on site

- The customer is also made aware of repair items or safety issues at the conclusion of the inspection